The Science and Art of Marble Polishing Transforming Surfaces into Mirror Finishes

Updated : 2 months ago

Marble has been a symbol of luxury and elegance for centuries, gracing everything from ancient sculptures to modern countertops. Its natural beauty and unique veining make it a sought-after material in architecture and design.

However, maintaining its pristine appearance requires more than just routine cleaning—it involves a meticulous polishing process.

In this blog post, we'll guide you through the step-by-step process of marble polishing, highlighting how each stage transforms the surface and how various diamond grit pads contribute to achieving that perfect shine.

Understanding the Nature of Marble

Before diving into the polishing process, it's crucial to grasp the inherent characteristics of marble, which influence how it responds to polishing.

● Composition: Marble is a metamorphic rock, primarily composed of recrystallized carbonate minerals, like calcite or dolomite.

● Porosity: Due to its crystalline structure, marble is relatively porous, making it susceptible to absorbing liquids and stains if not sealed properly.

● Surface Imperfections: Even when polished, marble has tiny surface imperfections that can accumulate scratches over time, dulling its shine.

The Marble Polishing Process Explained

Marble polishing is a precise, multistep procedure involving diamond abrasive pads of varying grit sizes. Each step serves a unique purpose in refining and perfecting the surface.

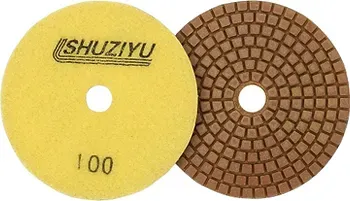

1. Initial Grinding with 100-Grit Diamond Pad

Purpose: To remove deep scratches, stains, and surface imperfections.

● The process begins with a coarse, 100-grit diamond pad attached to a heavy-duty floor machine.

● This pad contains larger diamond particles designed to grind down the surface.

Microscopic Action:

● The coarse diamonds shear off any protruding or uneven parts of the marble, leveling the surface.

● This step leaves fine scratches on the surface but removes major imperfections.

Outcome: The marble surface becomes flatter, though it will still look dull due to visible scratch marks.

2. Intermediate Grinding with 200-Grit Diamond Pad

Purpose: To smooth out the scratches left by the initial 100-grit grinding.

● The 200-grit diamond pad is finer and focuses on reducing the size and depth of the scratches from the previous step.

Microscopic Action:

● The smaller diamond particles further grind the surface, beginning to smooth it out.

Outcome: The marble surface becomes smoother, with less noticeable scratches, and starts to regain some of its natural sheen.

3. Progressive Polishing with Medium to Fine Grit Pads (400 to 800 Grit)

Purpose: To refine the surface and eliminate minor imperfections.

● In this stage, 400 and 800-grit pads are used sequentially to polish the marble.

Microscopic Action:

● Each finer grit removes the scratches left by the previous coarser pad.

● The surface becomes increasingly smooth, preparing for the final polishing stages.

Outcome: The marble takes on a satin-like finish, with scratches becoming barely visible.

4. Fine Polishing with Ultra-Fine Grit Pads (1500 to 3000 Grit)

Purpose: To achieve the desired high-gloss, mirror-like finish.

● The final polishing involves ultra-fine 1500 and 3000-grit pads, which polish rather than grind the surface.

Microscopic Action:

●These ultra-fine pads remove the tiniest of scratches and begin to close the microscopic pores of the marble, enhancing its reflectivity.

Outcome: A polished, luminous surface that evenly reflects light, giving the marble a vibrant, mirror-like appearance.

The Science Behind the Shine

Marble's transformation into a reflective surface is not just a matter of polishing—it’s the result of precise scientific processes.

●Microscopic Smoothness: The smoother a surface becomes, the more light it reflects. Polishing reduces the size of scratches down to a microscopic level, enabling uniform light reflection.

● Mirror Effect: When imperfections are minimized to the nanometer scale, marble can reflect images and light clearly, giving that coveted mirror-like finish.

The Role of Diamond Abrasives

Diamond abrasives are the unsung heroes in the marble polishing process. Here's why they are so crucial:

●Hardness: Diamonds are the hardest naturally occurring material, which makes them perfect for grinding and polishing hard surfaces like marble. They can remove even the toughest scratches and imperfections without causing additional damage.

● Precision: The use of diamond pads ensures precise abrasion, which is key to achieving the smoothest possible finish. This precision allows for controlled removal of imperfections, layer by layer, without affecting the integrity of the marble.

● Efficiency: Unlike other abrasives, diamond abrasives work more quickly and effectively, ensuring that each step—whether it's grinding or polishing—is done to perfection, minimizing the risk of uneven results.

The variety of grit sizes in diamond pads—from coarse to ultra-fine—ensures that each stage in the polishing process builds upon the last, steadily transforming the marble from rough to refined.

Additional Factors Influencing Marble Polishing

Beyond the diamond abrasives, several other factors influence how well your marble polishing efforts turn out:

1. Use of Water

Water plays a vital role in marble polishing, acting as:

● A Cooling Agent: Polishing generates heat from friction, and without water, the marble and diamond pads could overheat, potentially damaging the stone. Water keeps everything cool and safe.

● Lubrication: Water helps to reduce friction between the abrasive pads and the marble, allowing for smoother grinding and a more uniform finish.

● Dust Control: Marble dust can be hazardous and messy. Using water helps to suppress dust during the grinding and polishing process, making the work environment cleaner and safer.

2. Sealing Post-Polishing

After polishing, marble is left with an ultra-smooth surface, but it’s still porous. Sealing is essential to:

● Protect Against Stains: Without sealing, the porous nature of marble can lead to it absorbing liquids and becoming stained, especially from substances like wine, oil, or acidic juices.

● Extend the Finish: Sealing locks in that beautiful, polished finish, ensuring the marble maintains its mirror-like sheen for longer periods, reducing the need for frequent repolishing.

Why Each Step Matters in Marble Polishing

Skipping steps or rushing through the process can lead to:

● Incomplete Scratch Removal: Deeper scratches may remain, diminishing the overall finish.

● Inconsistent Shine: Polishing without a sequential progression of grit sizes can lead to uneven gloss, with patches of dullness.

● Reduced Durability: Improper grinding or polishing can weaken the marble, making it more prone to damage.

Everyday Analogies to Help Understand Marble Polishing

If you’re struggling to visualize the marble polishing process, here are some relatable analogies:

● Sanding Wood: Just like sanding wood, where you begin with coarse sandpaper and progressively use finer grits, marble polishing follows the same principle of layered refinement.

● Automotive Detailing: Much like car detailing, where abrasive compounds remove scratches and swirl marks from paint, marble polishing uses diamond abrasives to remove surface imperfections.

Conclusion

Marble polishing is a delicate balance of science and artistry. It’s not just about making a surface shiny; it’s about understanding how each grit size, each pass, and each stage plays a crucial role in the final result. From the initial grind that flattens the surface to the ultra-fine polishing that creates a mirror-like sheen, every step matters. Similarly, epoxy flooring offers a perfect blend of durability and aesthetics, creating surfaces that are both functional and visually appealing.

By understanding the intricacies of this process, whether you’re a homeowner looking to restore your marble floors or a professional in the industry, you can better appreciate the craftsmanship that goes into achieving that flawless, reflective finish.

So, the next time you walk across a gleaming marble floor, take a moment to appreciate the science and art behind that stunning surface.

References

Marble Institute of America. (n.d.). Marble Care and Maintenance. Retrieved from www.naturalstoneinstitute.org.

United States Geological Survey. (n.d.). The Geology of Marble. Retrieved from www.usgs.gov.

Diamond Tooling Systems. (n.d.). Understanding Diamond Abrasives. Retrieved from www.diamondtoolingsystems.com.

60 views

60

0 comments

0

Comments